I had the opportunity to tour the Irsching 4 power plant near Ingolstadt, Germany, and I was thrilled because I am an energy journalist who has covered power plants and turbine technology for over seven years. Modern gas turbine technology has never been more efficient than the two state-of-the-art Siemens J-class gas turbines housed in this cutting-edge complex. Irsching 4 is able to attain record-setting efficiency rates because to the technology behind these amazing turbines, which I will examine in detail in this blog post. Let’s read below about “Siemens J-Class Gas Turbines – Irsching 4 Power Plant in Germany”.

Table of Contents

Siemens J-Class Gas Turbines – Irsching 4 Power Plant in Germany

The Evolution of Siemens Gas Turbine Technology

For many years, Siemens has been the market leader in gas turbine technology. Both heavy-duty and aeroderivative gas turbine models are part of their extensive portfolio of 400 installations worldwide. After the G- and H-class turbines were so successful, the J-class represents the next big step ahead.

With each successive generation of gas turbines from Siemens, improvements in combustion systems, firing temperatures, materials, tighter clearances, and technology have led to a steady rise in efficiency. By integrating the greatest features of the G- and H-class units, the J-class has achieved a record-breaking efficiency of more than 63% for large-scale gas turbines.

The Irsching 4 Facility and J-Class Turbines

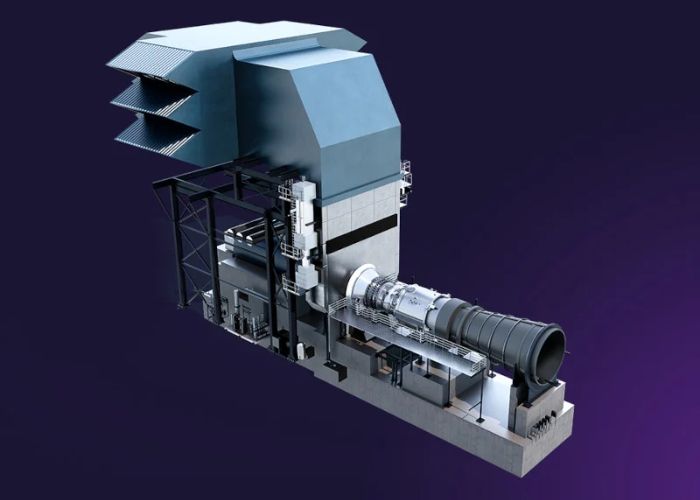

A pair of gas turbines from the SGT5-8000H series are housed at the Irsching 4 power station in Bavaria, Germany, which is situated to the south of Ingolstadt. Irsching 4, a combined cycle power plant with a total producing capacity of 578 MW, is among the most efficient on the planet. It performs exceptionally well in terms of combined cycle efficiency, reaching over 60%.

Read More:- GE H-Class Turbines – Top Gas Power Plants in the USA for 2024

Powering more than 2 million homes in the area, E.ON Kraftwerke GmbH runs the facility. In addition, a steam turbine is used to supply district heating to the surrounding area.

Irsching 4 is home to two massive J-class turbines; the height of the compressor blades is more than 8 feet. Here are a few important features and specifications:

- Generating capacity of 289 MW per turbine

- 38% thermal efficiency in simple cycle operation

- Firing temperature of over 2,700°F (1,500°C)

- 18-stage axial compressor with advanced 3D blading

- Can burn natural gas or fuel oil for flexibility

- DLN 2.6+ combustion system for low emissions

- Air-cooled generator for reduced water consumption

In terms of producing electricity, these state-of-the-art gas turbines provide significant benefits. Less fuel is needed per megawatt produced due to the high efficiency ratings. Their operational flexibility enables them to swiftly adjust to changes in renewable energy generation. Low nitrogen oxide (NOx) emissions are made possible by the DLN combustion system, which helps with environmental compliance.

Seeing the J-Class Turbines Up Close

The best part of my time at Irsching 4 was going up to the turbine deck to get a close look at the J-class turbines. Side by side, taking up about the same amount of room as a modest house, are two enormous turbines. When you stand near these machines, you can feel the tremendous pressures and temperatures that they work under.

According to wikipedia, Shaft speeds of the turbines exceed 1,500 feet per second, and they spin at 3000 rpm. Unique materials, such as nickel-based superalloys, are needed since the inlet temperature is higher than 1,500°C. Each turbine is monitored by hundreds of sensors to ensure optimal performance and problem prevention. The scale and accuracy of such technological operations astounds me.

I also got a tour of the control room, where operators keep an eye on the turbines using a number of monitors and may make remote adjustments if necessary. Turbines’ fuel, combustion, steam, and exhaust systems are each controlled by their own individual control cabinet.

The stark contrast between the modern control room and the sterile turbine deck brought home just how much of a game-changer computers and automation have been in the power plant industry. Once requiring dozens of workers, systems can now be managed by a small team of technicians.

Efficiency and Flexibility

Having seen the Irsching 4 plant in person, I can attest to the J-class turbine’s status as a benchmark for combined cycle efficiency. Compared to earlier generations of gas turbines, this plant gets more power out of less fuel because to its efficiency rating of over 60%.

Thanks to its fast ramp rates and dual-fuel capability, the J-class also provides vital operating flexibility. Because of this, it works well with renewable energy sources with fluctuating output, such as solar and wind. To maintain grid stability as renewable energy sources change, the turbine can rapidly increase or decrease its output.

The DLN 2.6+ combustion system reduces NOx emissions, which helps with environmental compliance. One of the cleanest thermal power sources currently accessible, thanks to the combination of this and the high efficiency.

Conclusion

The technological innovation at the heart of modern power generation is the Siemens J-class gas turbine. Thanks to the record-breaking efficiency ratings, fuel costs and emissions can be reduced. Siemens has demonstrated proficiency in implementing this technology on a large scale with more than 400 gas turbine installations globally.

You may see the J-class turbines in action at the Irsching 4 facility. Their performance and engineering are second to none, and I was astounded by them when I saw them in person. To counteract the unpredictability of renewable energy sources, gas turbines such as the J-class will play a larger role in the future of the power system. In this crucial area of technology, Siemens remains at the forefront of innovation. I hope you like reading “Siemens J-Class Gas Turbines – Irsching 4 Power Plant in Germany”.

Mohsen Ali is a Chemical Engineer with over a decade of experience in the energy sector. Specializing in power plant efficiency and sustainability, he brings expert insights to borderpowerplants.org. Mohsen holds a Master’s degree in Chemical Engineering and is dedicated to advancing sustainable energy solutions. Connect with him on Instagram or LinkedIn for more insights.